Setting up a workshop – whether it’s in your garage, basement, or a dedicated outbuilding – almost always starts with picking out a solid workbench. This isn’t just any piece of furniture; it’s where you’ll handle projects on a regular basis. Basically, the workbench becomes the center of your workspace.

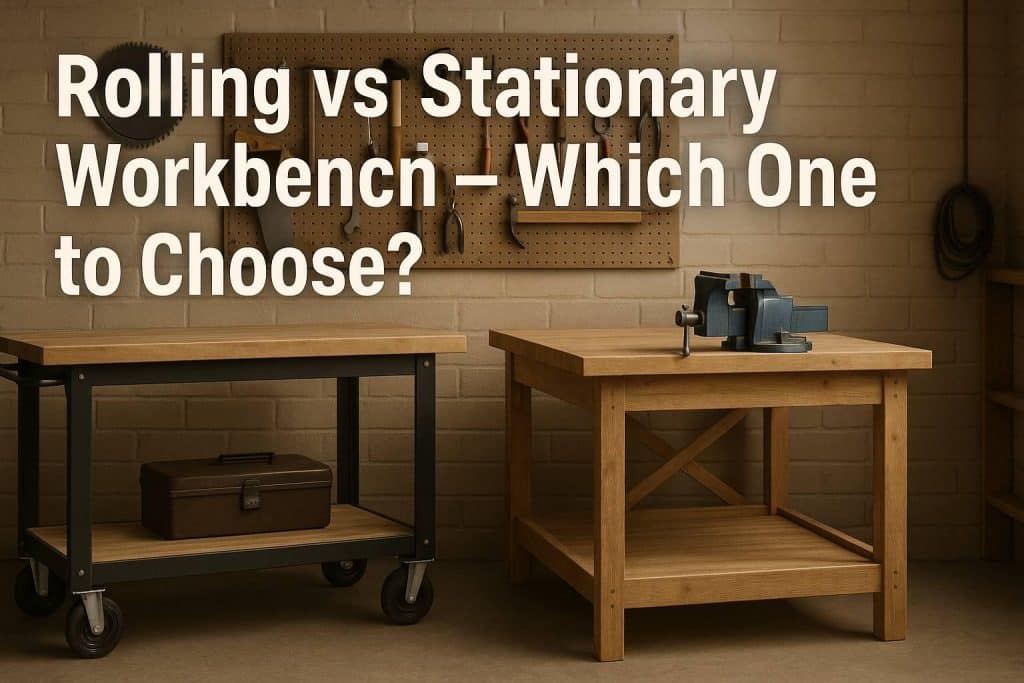

When you’re deciding between a stationary workbench or a rolling one, it’s worth taking some time. That choice can shape how you work and how smoothly things go. Here’s a breakdown to help you figure out what’s right for you.

What Are Rolling and Stationary Workbenches?

Let’s clear up what these two types actually are. A stationary workbench stays right where you put it. Usually, it’s heavy and built to take a beating – moving it isn’t part of the plan. For extra stability, most people set these benches against a wall or even anchor them in place.

Rolling workbenches change things up with casters – sturdy wheels that let you move the whole bench around the shop. They’re perfect if you need to shift your workspace on the fly or want to bring your work surface closer to big tools or projects. You can lock the wheels when you want it to stay put, so you get a mix of mobility and stability. Check heavy-duty rolling workbenches at Dyco Ventures with an array of custom options to choose from.

Key Features Comparison Table

|

Feature |

Rolling Workbench |

Stationary Workbench |

|---|---|---|

|

Mobility |

High – easy to move |

None – fixed position |

|

Stability |

Moderate with locking wheels |

Excellent |

|

Load Capacity |

Moderate to high |

Very high |

|

Space Optimization |

Flexible |

Limited |

|

Cost |

Generally higher due to casters |

Often more affordable |

|

Maintenance |

Requires occasional caster upkeep |

Minimal maintenance |

Advantages of Rolling Workbenches

Rolling workbenches have become pretty popular in both pro shops and home garages, mostly because they’re so easy to move. That mobility lets you rearrange your workspace on the fly – super useful if you’re tight on space or want to use your garage for more than just projects.

Cleaning’s also a breeze. Since you can wheel the bench out of the way, it’s simple to sweep or mop spots that would otherwise collect junk, dust, or spilled stuff. Plus, a lot of rolling benches come with built-in storage – think drawers, shelves, or even pegboards – so you get more bang for your buck when it comes to staying organized.

Drawbacks of Rolling Workbenches

But there are downsides too. Even if you lock the wheels, rolling benches just aren’t as rock-solid as stationary ones. If you’re doing something that needs a really steady surface – like heavy hammering, metalwork, or detailed woodworking – you’ll probably notice more wobble or vibration than you’d like.

Another thing: rolling workbenches usually cost more. The extra features, like sturdy wheels and good hardware, bump up the price. And don’t forget, you’ll have to keep those wheels in good shape if you want the bench to roll smoothly and safely over time.

Advantages of Stationary Workbenches

Stationary workbenches are a classic pick if you’ve got plenty of room to work with. The main thing they offer is rock-solid stability. They’re built to handle heavy equipment, oversized materials, and tough projects – without budging or wobbling.

Another perk: they can take a lot of weight. Thanks to their thick frames and sturdy build, stationary benches fit right in when you’re dealing with woodworking, metalwork, or car repairs. Since they don’t move around, it’s also easy to wire up outlets, set up tool storage, or hook in dust collection right where you need it.

Drawbacks of Stationary Workbenches

Steady beches aren’t going anywhere once you set them up. If you want to rearrange your space, moving a stationary bench usually means breaking it down – definitely not quick or easy. That makes them a tricky fit for small or shared workshops that need to stay flexible.

They also have a pretty big footprint. Because these benches are often big and heavy, they can eat up precious space. For casual DIYers or people working out of a cramped garage, that can be a real drawback.

Factors to Consider When Choosing

Deciding between a rolling or stationary workbench really comes down to a few key things:

- Space: If you’re working in a cramped spot or need to share the area, a rolling bench gives you some wiggle room. But for bigger workshops that aren’t going anywhere, a fixed bench is hard to beat in terms of sturdiness.

- The Work Itself: Heavy-duty projects want a stationary setup. For lighter tasks or the occasional DIY, a rolling bench does the trick.

- Budget: Usually, rolling benches cost a bit more upfront. If you’re trying to save money, a stationary bench can deliver solid performance for less.

- Down the Line: Think about whether you’ll want to rearrange things later. Rolling benches make that way easier, while stationary ones are meant to stay put.

Expert Tips for Optimal Workbench Setup

Whatever style you go with, there are a few smart ways to upgrade your workbench:

- Tool Storage: Built-in drawers, shelves, or even a simple pegboard can keep your gear tidy and always close by.

- Lighting: Good, bright lighting that you can adjust makes a huge difference – your eyes (and your accuracy) will thank you.

- Surface Material: Pick a tough work surface that fits your projects – hardwood, stainless steel, or laminated plywood are all solid picks, depending on what you’re working with.

- Safety Features: Don’t leave sharp tools out – store them safely. And if you’re on your feet a lot, an anti-fatigue mat really helps.

Maintenance and Longevity

If you take care of your workbench – whether it moves or stays put – you’ll get years of solid use out of it. For rolling benches, check in on the casters now and then (they need a bit of lubrication) and make sure the locking systems still work the way they should. With stationary benches, it’s a good idea to tighten up any loose joints or fasteners, especially if you put them through heavy lifting.

And honestly, just keeping your work surface and storage spaces clean makes a big difference. Wiping away dust, grease, or the occasional rust spot keeps your bench not only usable but also looking good.

Conclusion

There’s no one-size-fits-all here. Rolling benches are hard to beat when it comes to flexibility, while stationary models are built for serious stability and heavy work. It really comes down to what you need, how much room you have, and what kind of projects you tackle. Weigh your priorities, and you’ll end up with a bench that makes your space safer, more enjoyable, and just plain better to work in – year after year.