You’ve probably seen those sturdy outdoor chairs that look like wood but never seem to fade or crack. I get it, shopping for patio furniture can be confusing when terms like “polywood,” “POLYWOOD,” and “composite” get thrown around interchangeably.

I’ll clear up this material mystery for you. You’ll learn exactly what goes into making polywood furniture and why it performs so well outdoors.

If you’re wondering what is polywood made of, then this blog post will break down the specific materials used in polywood creation and compare it with different materials.

Its helps you understand what makes this recycled plastic lumber so durable and eco-friendly for your patio.

What is Polywood?

Let me clear up some confusion right away. When I first heard about polywood, I thought it was some fancy type of plywood. But I was wrong.

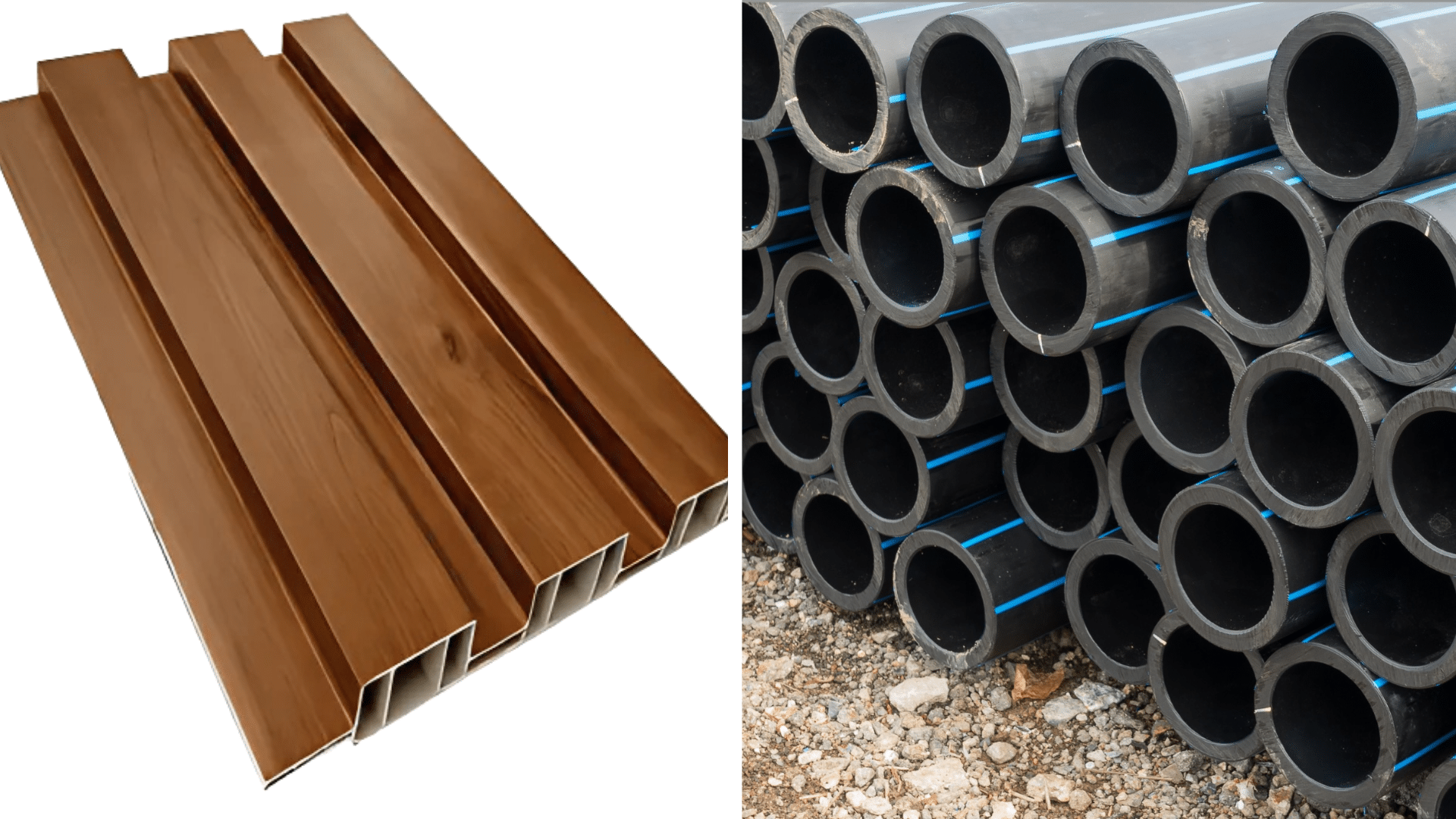

Polywood is actually made from recycled plastic lumber, designed to look and feel like traditional wood. It’s made primarily from high-density polyethylene (HDPE), think recycled milk jugs and detergent bottles that get a second life as furniture material.

- Generic polywood lumber: This is the general term for any HDPE plastic lumber made from recycled materials

- POLYWOOD® (the brand): This is a specific company that makes premium polywood furniture using its own proprietary process

It’s like how we say “Kleenex” when we mean any tissue. Many people simply say “polywood” when referring to the POLYWOOD brand specifically.

Where You’ll See Polywood?

I’ve noticed polywood popping up everywhere in outdoor spaces, and for good reason:

- Patio furniture: Chairs, tables, benches, and dining sets

- Adirondack chairs: These are hugely popular in plywood

- Deck railings and trim: Weather-resistant and low-maintenance

- Outdoor storage solutions: Sheds, storage boxes, and planters

- Playground equipment: Safe, splinter-free, and durable

What is Polywood Made Of?

When people ask me what’s actually in polywood, I love sharing this because it’s pretty cool from an environmental standpoint.

Polywood is made primarily from High-Density Polyethylene (HDPE) – a specific type of plastic that’s incredibly durable and weather-resistant. But here’s the best part: most polywood comes from recycled materials.

The main ingredient in polywood composition is HDPE plastic. This plastic is:

- Extremely dense and strong

- Chemical resistant; Won’t break down from cleaning products or weather

- UV stable. Resists fading from constant sun exposure

- Non-toxic. Safe for outdoor use and contact

HDPE vs Polywood: Are They the Same?

I get this question a lot, and I totally understand the confusion when it comes to hdpe vs polywood. Let me break down the relationship because they’re related but not exactly the same thing.

The simple answer: Polywood is made from HDPE, but HDPE isn’t always Polywood. Think of it like this – all polywood contains HDPE, but not all HDPE products are polywood.

Understanding the Relationship

HDPE: This is the raw material (High-Density Polyethylene plastic)

Polywood: This is the finished product made from HDPE that’s designed to look like wood

It’s similar to saying “steel vs car.” Steel is the material, and a car is one of many things you can make from steel.

The Key Differences

| Feature | Raw HDPE Plastic | Polywood (Processed HDPE) |

|---|---|---|

| Form & Shape | Can be any shape or form | Specifically shaped like lumber |

| UV Protection | Might not have UV protection | Enhanced with UV stabilizers |

| Color Options | Usually clear or basic colors | Infused with colorants for rich, lasting colors |

| Appearance | Utilitarian look | Designed to mimic natural wood grain |

| Common Uses | Bottles, containers, pipes | Outdoor furniture, decking, railings |

| Durability & Design | Functional but not aesthetic | Engineered for weather resistance and visual appeal |

Why is Polywood Popular for Outdoor Furniture?

I’ve watched polywood furniture take over patios and decks everywhere, and honestly, it makes total sense once you understand what you’re getting.

1. It laughs at weather while wood cries: I’ve seen polywood chairs sit through brutal winters, scorching summers, and endless rainstorms without a scratch.

Meanwhile, my neighbor’s wooden deck furniture warped so badly after one season that half the pieces became unusable. Polywood doesn’t rot, warp, split, or fade like traditional wood does.

2. Zero maintenance means more time relaxing: I literally hose off my polywood furniture when it gets dirty, and that’s it. No sanding, no staining, no sealing every year like wood requires.

My friend spends entire weekends maintaining his wooden outdoor set, while I’m already enjoying a cold drink on mine.

3. Bugs can’t eat plastic, but they devour wood: Termites, carpenter ants, and other insects see wooden furniture as an all-you-can-eat buffet. Polywood? They can’t even make a dent in it.

I’ve never had to worry about insect damage, which is a huge relief compared to constantly checking wood furniture for signs of bug problems.

4. Brand trust drives market demand: Companies like POLYWOOD® and Trex® have built solid reputations over decades, and people notice quality.

When customers see these brands lasting 10-15 years with minimal care while cheaper wood furniture falls apart in 2-3 years, word spreads fast. The initial investment pays off when you’re not replacing furniture every few seasons.

Polywood vs Composite vs Traditional Lumber

| Material | Description | Pros | Cons |

|---|---|---|---|

| Polywood | 100% recycled HDPE plastic, wood-like appearance | No maintenance, weatherproof, very durable | Heavier, higher upfront cost |

| Composite | Blend of wood fibers and plastic resins | Wood-like feel, low-maintenance, affordable alternative | Can scratch, less natural than wood |

| Traditional Lumber | Natural wood (treated or untreated) | Authentic look, lowest initial cost | High maintenance, prone to warping/rotting over time |

Style and Customization Tips

When friends ask me what is polywood made of, they’re surprised to learn it’s recycled plastic, not wood. What amazes me even more is how stylish and customizable it’s become over the years.

- Polywood is now available in a wide variety of vibrant and neutral colors, from teak and mahogany tones to bold shades like blue, green, orange, and white.

- Modern finishes include both smooth and textured surfaces, closely mimicking real wood grain.

- Fits any style, from rustic and classic to sleek and modern, easily adapting to different outdoor settings.

- Mix and match different colors in the same set without worrying about fading or uneven aging.

- Pairing with cushions and accessories is simple, as the color and finish stay consistent over time.

- Leading brands now offer over 20 fade-resistant color options, and you can request samples before buying.

To Conclude

Now you know exactly what is polywood made of HDPE plastic from recycled milk jugs and bottles, transformed into furniture that outlasts traditional wood by years.

I’ve covered the key differences between polywood, composite, and traditional lumber, as well as why this recycled plastic material has become the go-to choice for outdoor spaces.

So what’s next? If you’re tired of replacing wooden furniture every few seasons, it might be time to consider making the switch.

What’s your biggest concern about choosing polywood over traditional wood?